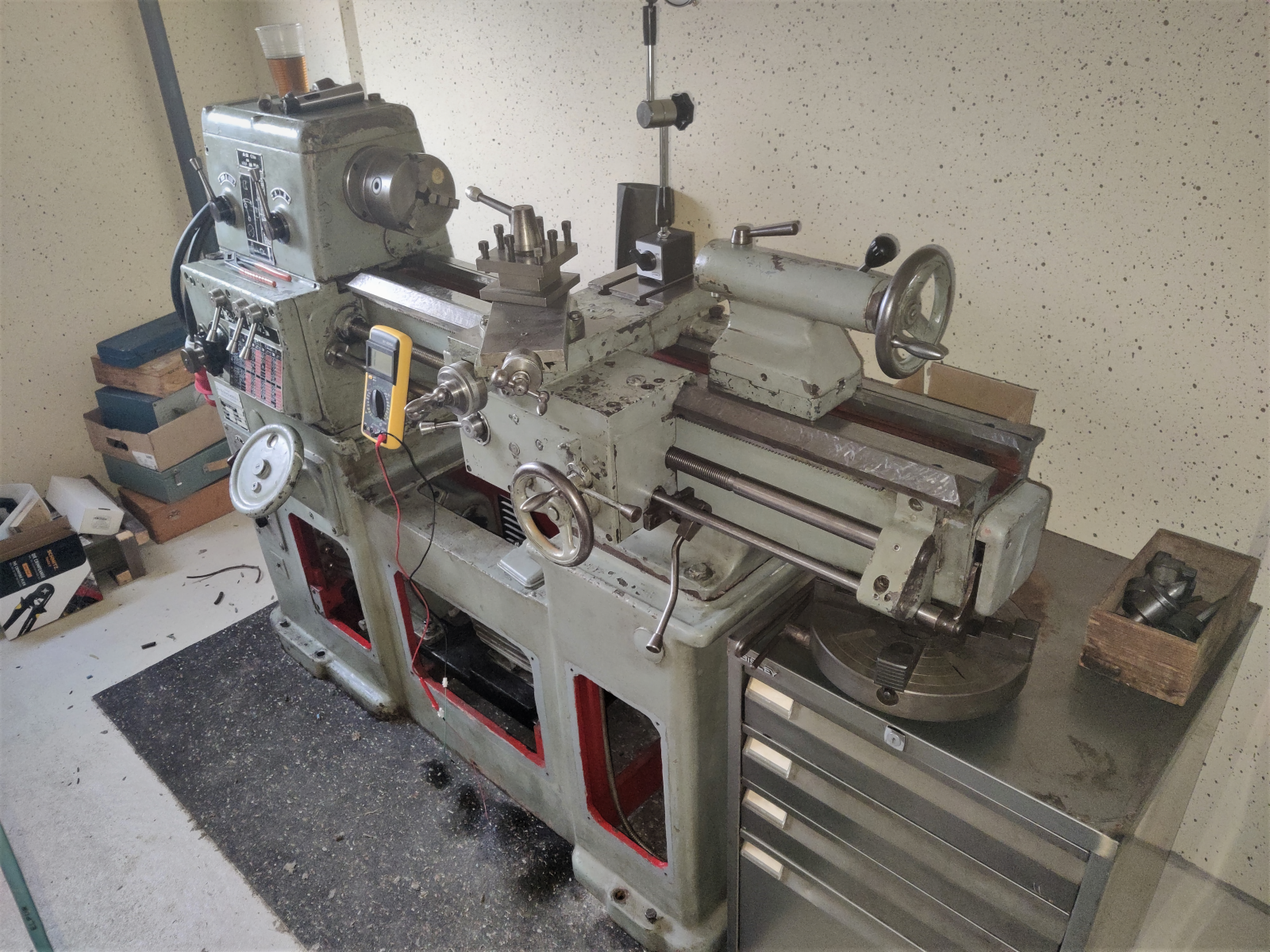

My Kart E2N-750 lathe

This is my little toolroom lathe. It's a Hungarian E2N-750 from 1974.

I bought this lathe back in June 2021 as a replacement for the chinese mini-lathe I used at home before. Originally I was looking at East German DLZ-type lathes, but happened to stumble upon this machine.

The repair

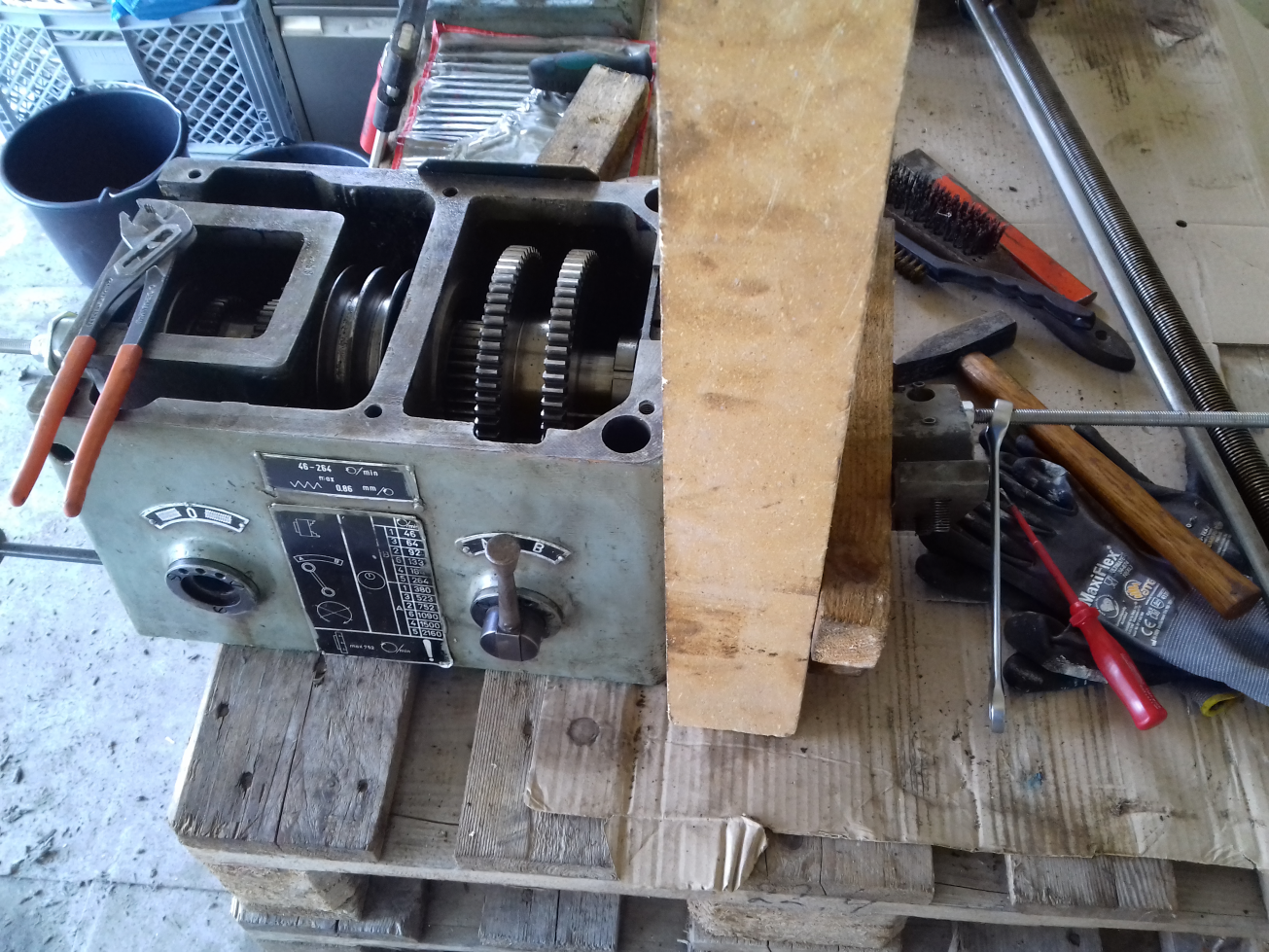

So I took the opportunity and bought this lathe used non-running for a fair price and set out to get it running again. I knew the error was likely electrical, so I procrastinated and started work on the mechanical parts instead. I did some research and eventually got my hands on an owners manual (contact me for more information) and some drawings. Using these, I decided to do a full teardown on the machine. Thus I could not only clean it, but also stop the many oil leaks this machine had. During the teardown I found out the machine bed had about a quarter millimeter run-in and an axial bearing in the headstock was shot.

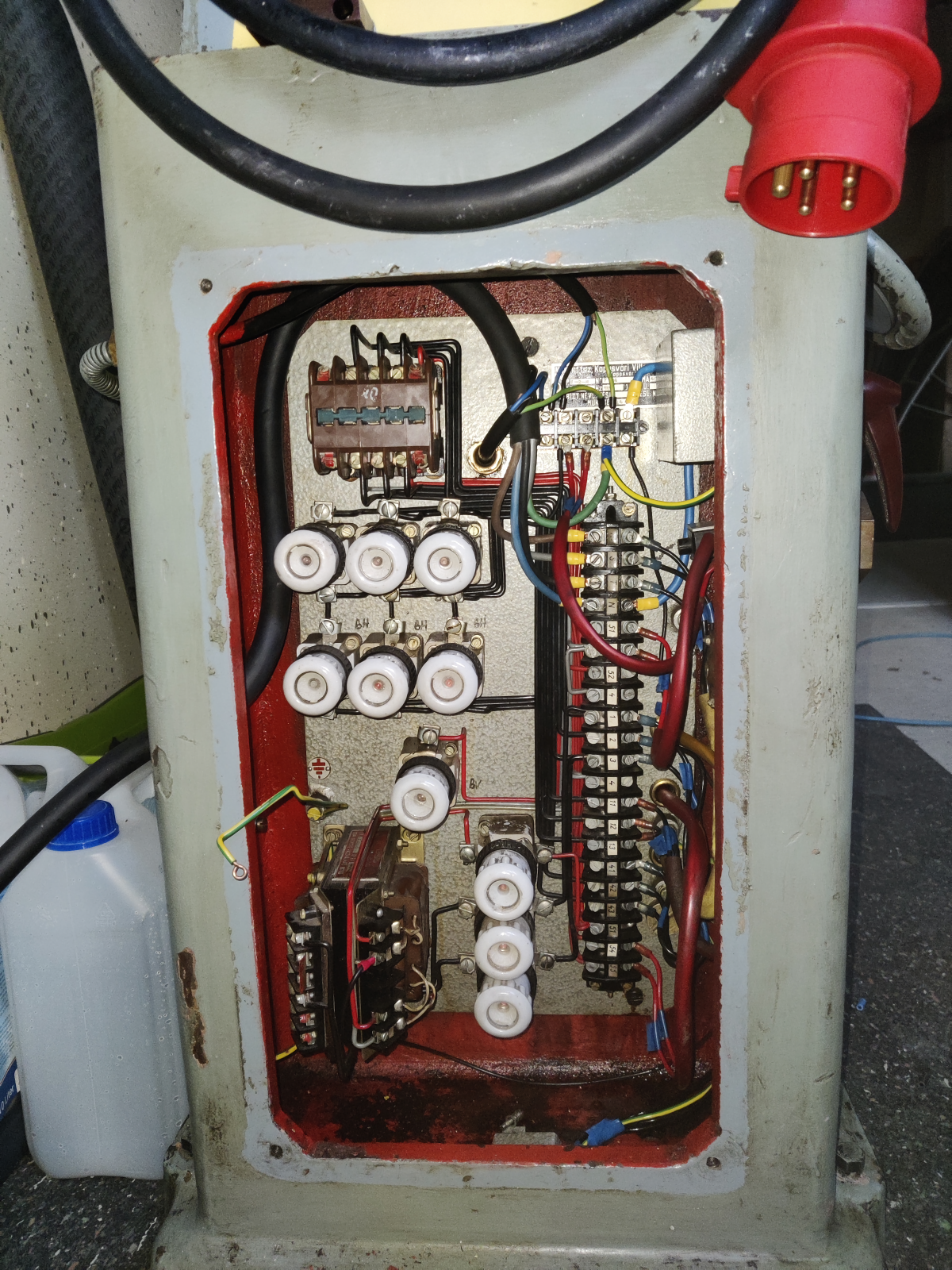

So I had to re-scrape the bed and pull the spindle. This is quite an ordeal with any lathe really and took some time. A few months later in October, I finally started work on the electric system. It is quite sophisticated for a 1974 lathe. The wiring in the cabinet is simply a work of art. The lathe utilises ceramic fuses and basically only relays to control the current, which makes the electrical system really robust. The error was in a broken lockout/safety switch, so I got the electrical system rewired and running in no time. In the end, fixing the electrical system was the easiest part of this whole restoration.

Features

The only question remaining was: Will it lathe?

Yes it will, quite respectably actually for a 50-ish year old lathe this size.

I am really pleased with this lathe because of certain features: It has a 3-phase motor delivering plenty of torque at 50Hz. With modern CNC machines, a lathe usually has a overkill motor (a lathe this size would probably have a 10kW motor in it) and a VFD, creating a variable torque curve across frequencies. This lathe however is geared and thus (if set correctly) never stalls the motor. If one would try to take for example a DOC of 5cm, the lathe would probably break the tool with the lathe being all cast steel and built like a tank. I did crash it already (anybody owning machine tools who says he never crashed them is lying), and on one instance it snapped a 14x14mm HSS tool in half (like ?!?).

The gearbox allows for 12 speeds from 46 to 2160 RPM. Thus it can also easily run Carbide tooling on somewhat small parts (still achieving the necessary surface speeds). The main advantage of this lathe compared to other lathes of the era is in my opinion the build quality along with its versatility. The next project up would be a new paint job and a big 6-jaw chuck for this lathe. In the meantime I will probably get my fair share of time on it building mostly engine parts, adapters and oddly specific tools/spare parts you can't just buy with Amazon.